The H2POD™ powered by i-phi™ is a Hydrogen Generating System for internal combustion applications. The H2POD™ produces a mixture of hydrogen and oxygen gases, on demand, through a controlled electrolysis process. It is designed to work on any internal combustion engine. It operates on demand only when the engine is running thus eliminates the need for on-board Hydrogen storage and addresses all safety concerns

. Canadian Technology

. Robust and designed for long life

. Requires no maintenance

. Payback can be less than one year

The H2POD™ System powered by i-phi™produces a mixture of hydrogen on demand with oxygen gases through a controlled electrolysis process. These gases are delivered to the engine’s air intake, where they are mixed with the air and enter the engine’s cylinders, participating in the combustion process.

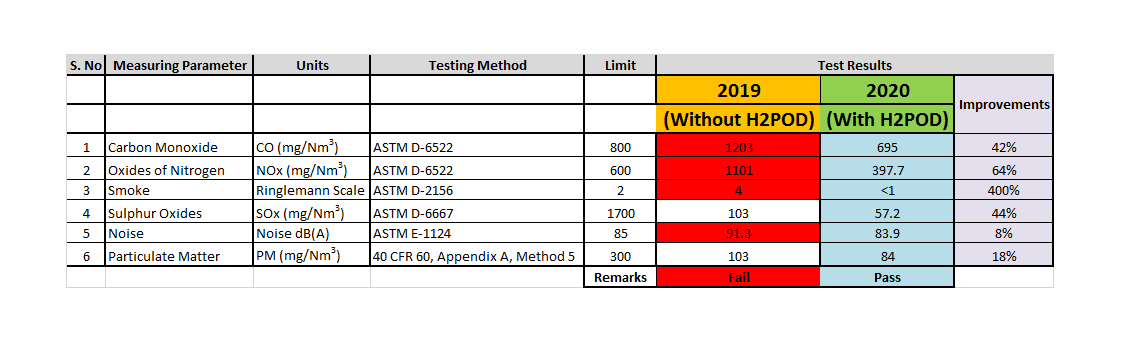

Adding hydrogen through the H2POD™ System to a diesel engine improves overall engine combustion efficiency by producing a more complete burn. This results in a decrease in greenhouse gases, reduced emissions and decreased fuel consumption.

Hydrogen burns significantly faster than fossil fuels and with a significantly Lower Flammability Limit. Both of these factors lead to small amounts of Hydrogen having significant effects on combustion. The first and most important effect for our purposes is that the Hydrogen promotes a faster and more complete burn of the fuel, closer to the top of the power stroke in an engine. This leads to increased thermal efficiency which necessarily leads to less fuel spent for a given amount of work. In addition, Hydrogen has a significant stabilizing effect on cycle-to-cycle variations in combustion, which leads to further efficiency improvements.

The addition of Hydrogen to the combustion cycle also has significant effects on emissions, both due to the properties of Hydrogen in combustion itself and due to the increased thermal efficiency resulting from the Hydrogen-enhanced combustion. A faster and more complete burn leads to dramatic reductions in unburnt hydrocarbons (Particulate Matter) and in Carbon Monoxide (CO). The increased fuel economy leads to a reduction in Carbon Dioxide levels (CO2), and the higher thermal efficiency of the combustion cycle leads to lower exhaust temperatures, which leads to a reduction in Nitrous Oxides (NOx).

Engine Displacement: 1

– 10 Liter

Dimensions: L-36”x W-18”xH-32"

Weight: 66 Kg

Water Tank Capacity: 10

Liters

Water Consumption: 50

ml / Hour

Power

Input: 110/220

V

Power

Consumption: 700 W

Operating

Temp Range: -40 C to

+85 C

Engine Displacement: Upto 15 Liter

Dimensions: L-22”x W-8.5”xH-19"

Weight: 40 Kg

Water Tank Capacity: 8 Liters

Water Consumption: 70

ml / Hour

Power

Input: 12/24 V

Power

Consumption: 25

Amp @ 12 V

12.5 Amp @ 24 V

Operating

Temp Range: -40 C to

+85 C

System Monitoring: GSM/GPRS/WiFi

Engine Displacement: 10 Liter and up

Dimensions: L-60”x W-26”xH-48"

Weight: 250 Kg & up

Water Tank Capacity: 40

Liters

Water Consumption: 70

ml / Hour & up

Power

Input: 110/220/440 V

Power

Consumption: 1.5 kWh & up

Operating

Temp Range: -40 C to

+85 C

System Monitoring: GSM/GPRS/WiFi